Understanding Sportswear Manufacturing: The Reality of Small Orders

Introduction

The sportswear manufacturing industry, a crucial pillar of the global fashion sector, is often misunderstood, especially by newcomers and small-scale business buyers. At the heart of this misunderstanding lies the common assumption that garment factories, being labor-intensive, should readily accept small orders. This misconception overlooks the complex realities and challenges factories face. In this blog, we’ll dive deep into these challenges, dissecting why sportswear factories often hesitate or even refuse small orders. From high communication costs and efficiency challenges to cost control, risk aversion, and the specific conditions of factories, we will explore the multi-faceted nature of this issue. Understanding these intricacies is vital for start-ups and small businesses eyeing a venture into the sportswear market.

The High Cost of Communication and Efficiency Challenges

Communication is the cornerstone of any successful business transaction. However, in the sportswear manufacturing industry, effective communication is not just a necessity but a significant cost factor, especially with start-ups. New entrants, often unfamiliar with the intricate processes of garment production, require extensive guidance and frequent explanations. This necessity for repeated communication consumes a substantial amount of time and resources, leading to inefficiency.

The pre-production phase illustrates this challenge aptly. While initial samples may be approved by the client, discrepancies often emerge post-production. These discrepancies can stem from misunderstandings or changes in requirements, leading to time-consuming and costly revisions. The result is a tangled web of negotiations and rework, which is disproportionately burdensome for small orders. The effort expended in rectifying these issues for a small batch of products often outweighs the potential profit, making small orders less appealing for factories focused on efficiency and cost-effectiveness.

Cost Implications of Small vs Large Orders

To understand the reluctance of sportswear factories in accepting small orders, a closer look at the economics of production is essential. Contrary to popular belief, the production cost for a small order is not significantly less than that for a large order. Let’s consider the example of a bed-cutting worker, whose daily wage is $40. In the case of a small order, if only 50 pieces are cut per day, the labor cost per garment is $1.2. Conversely, for a large order where 600 pieces are cut daily, the cost drops to $0.2 per piece.

This cost difference becomes even more pronounced when considering other factors like purchasing and handling surface accessories. For instance, zippers and buttons are often sold in bulk, and the excess material in small orders becomes a wasted expense. These costs, although seemingly minor, accumulate and significantly inflate the total production cost for small orders.

Moreover, the labor costs for handling these accessories are the same for small and large orders. This uniformity in handling costs, combined with the higher per-unit material cost in small orders, leads to a situation where small orders become less economically viable. If the total cost exceeds the procurement budget of a buyer, it renders the entire exercise futile. Hence, factories often favor larger orders where the economies of scale allow for more efficient cost distribution and higher profit margins.

Risk Management and Start-Up Volatility

One of the less discussed, yet significant, factors influencing sportswear factories’ hesitation towards small orders is the inherent risk associated with start-ups. Start-ups, driven by enthusiasm and innovation, often lack a robust understanding of risk management. This lack of risk awareness can lead to instability, both in operations and financial commitments.

Factories frequently encounter scenarios where start-ups, after initiating the production process, face founder-related issues or financial constraints, leading to delayed payments or complete abandonment of the order. Such situations leave factories with unsold inventory and unrecovered costs, creating a financial strain. The advance payment often doesn’t cover the total investment made by the factory, and unsettled balances become a burden.

Given this potential for financial risk, factories are naturally cautious. They assess the financial stability and track record of start-ups before accepting orders. This risk aversion, while protective for the factories, often translates into reluctance to engage with small orders from relatively unknown or new businesses. The unpredictable nature of start-up operations thus becomes a deterrent for factories in accepting small-scale orders.

Factory Specialization and Order Acceptance

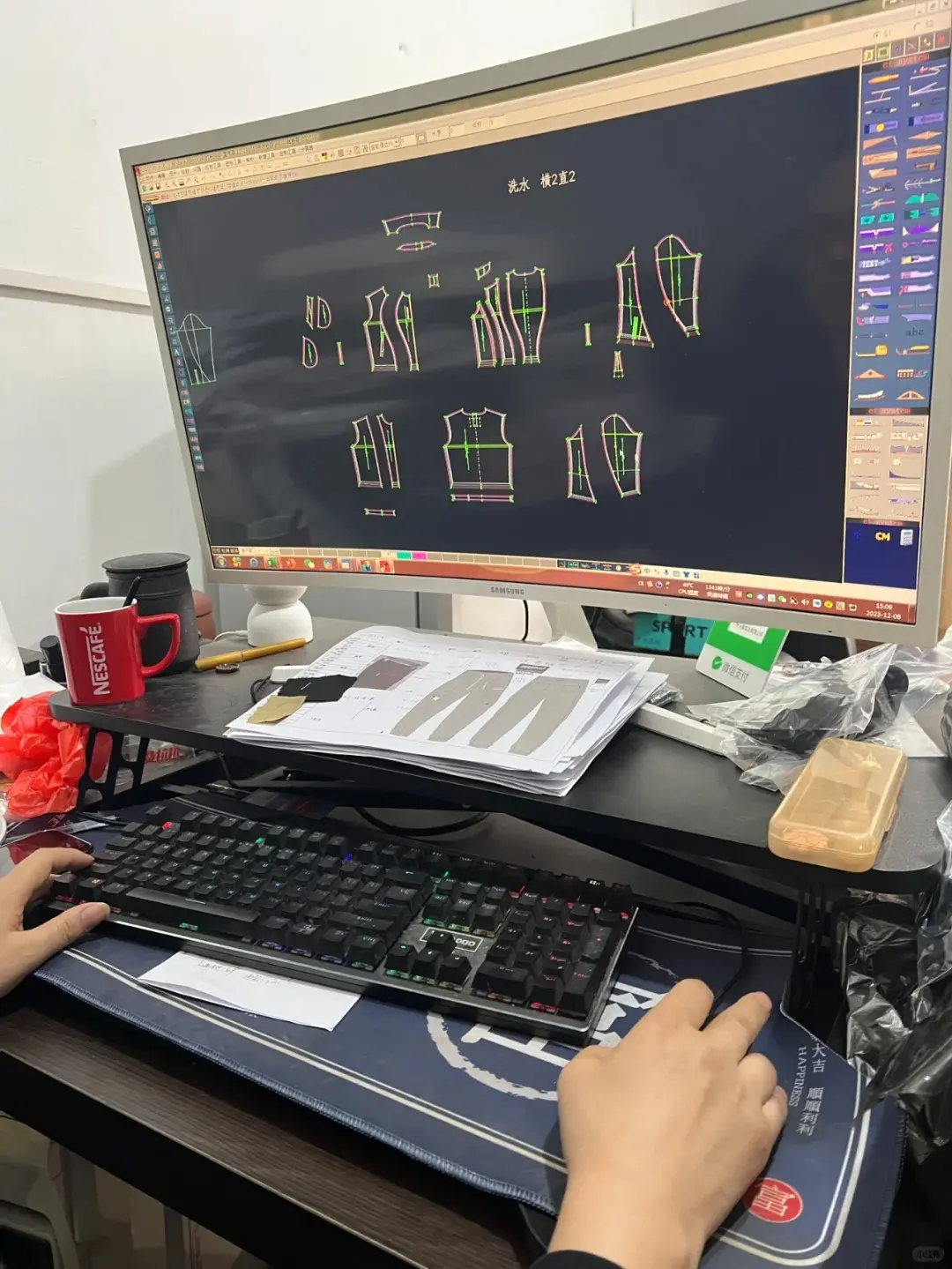

The specialization of sportswear factories plays a pivotal role in their order acceptance decisions. Many smaller factories are highly specialized, focusing on specific types of clothing such as knitwear, chiffon, pants, or denim. This specialization means that they are equipped and skilled to produce certain garments but may not be able to efficiently handle orders outside their expertise.

When start-ups or small businesses approach these specialized factories with diverse clothing requirements, the mismatch in capabilities often leads to the rejection of the order. Additionally, factories without in-house pattern makers or those that depend on certain established processes are less inclined to take on small orders, which might require a unique set of skills or disrupt their regular workflow.

Moreover, the long-term vision of a factory also influences their decision-making. Factories evaluate potential new clients on various parameters: the likelihood of long-term cooperation, profit margins, quality and delivery requirements, and payment capabilities. This evaluation helps them determine whether the partnership would be beneficial in the long run. Consequently, a factory might decline a small order not just based on the order size but also on the broader context of the business relationship and alignment with their expertise and operational model.

Conclusion

In conclusion, the reluctance of sportswear factories to accept small orders is a multifaceted issue, rooted in practical business considerations. From high communication costs and the complexities of cost distribution in small versus large orders to the inherent risks associated with start-ups and the specialized nature of many factories, these challenges highlight the need for a deeper understanding and strategic planning by business buyers. As the sportswear manufacturing industry evolves, it’s essential for both factories and businesses to find common ground, fostering cooperation and sustainable partnerships. Such mutual understanding is key to navigating the dynamic landscape of sportswear manufacturing.