This study selects sportswear fabrics labeled as quick-drying and moisture-absorbing, which are routinely tested in our laboratory. Tests are conducted in accordance with the moisture absorption and quick-drying evaluation standard GB/T 21665.1—2008. The performance of these fabrics is then analyzed in relation to their fabric structure and fiber properties. Results indicate that quick-drying and moisture-absorbing sportswear are typically made from synthetic fiber fabrics. In terms of comprehensive performance, knitted fabrics outperform woven ones, mesh and jacquard fabrics are superior to plain weave fabrics, low-yarn fabrics are better than high-yarn ones, and irregular fibers or fibers with surface grooves can improve the moisture absorption and quick-drying performance of the fabric. The use of modified polyester fibers can enhance the moisture-absorbing capacity of the fabric.

Keywords: Sportswear fabric; Moisture absorption and quick-drying properties; Fabric structure; Fiber properties

1.Introduction:

The moisture absorption of quick-drying products refers to the ability of fibers to absorb liquid water, while quick-drying refers to the fibers quickly transferring liquid water to the fabric surface, thereby achieving a quick-drying effect. The samples used in this study are sportswear fabrics labeled as quick-drying and moisture-absorbing, which are routinely tested in our laboratory. Tests are carried out following the methods and standard values stipulated in the recommended national standard GB/T 21665.1—2008, evaluating their moisture absorption and quick-drying properties. By comparing and analyzing the influence of fabric structure and fiber properties on these properties, we aim to provide reference for manufacturers of quick-drying and moisture-absorbing sportswear.

2.Experiment Section

2.1. Experimental Materials and Instruments Fabrics

The sportswear fabrics, routinely tested in our lab, were used in this study. They were made primarily of synthetic fibers, including polyester fibers, nylon and their blended fabrics, with a small amount of polyester-cotton blended fabrics. In order to analyze the effects of fabric structure and fiber properties on the fabric’s moisture absorption and quick-drying properties, we analyzed all samples in terms of fiber longitudinal and cross-section, etc. The main instruments used included biological microscope (BX43), Harris microtome (Y172 model), electronic balance (accuracy 0.001g), drying speed tester (DST 5200B), capillary effect tester (YG871), permeability test box (DH-450), oven, and dryer (equipped with color-changing silica gel), etc.

2.2. Experimental Conditions

The preconditioning time was not less than 24 hours. Both preconditioning and testing were carried out in a constant temperature and humidity laboratory with a temperature of (20±2)℃ and relative humidity of (65±3)%. To reduce the impact of the finishing process, all samples were washed 5 times according to the standard GB/T 8629—2017 program 4N (A1 standard washing machine) and dried in an oven.

2.3. Test Method

2.3.1. Water Absorption

Rate For each sample, cut five pieces that are not smaller than 10cm x 10cm. After pre-conditioning, measure the initial weight, then immerse the sample in grade-3 water. Once it sinks naturally and is fully wetted after about 5 minutes, hang it vertically. When the interval between two drops of water is no less than 30 seconds, you can remove the sample and measure its weight. The test result is the average of the five samples.

2.3.2. Water Droplet Diffusion Time

For each sample, cut five pieces that are not smaller than 10cm x 10cm. After pre-conditioning, lightly drip 0.2mL of grade-3 water onto the sample using a dropper. Record the time from when the water droplet contacts the surface of the sample until it fully diffuses. The water droplet diffusion time of each sample is the average time of the five samples.

2.3.3. Moisture Evaporation

Rate For each sample, cut five pieces that are not smaller than 10cm x 10cm. After pre-conditioning, measure the initial weight, then drip 0.2mL of grade-3 water onto the sample. Hang it vertically on the drying speed tester. Weigh the sample every minute, and stop the test when the rate of change between two consecutive weights is no more than 1%. The test result for each sample is the average of the five samples.

2.3.4. Core Absorption

Height For each sample, cut three pieces in both weft and warp direction, each measuring 30cm x 3cm. After conditioning, place them on the capillary effect tester. After 30 minutes, measure the minimum core absorption height on the samples. Calculate the average of the minimum core absorption heights in both directions, then take the higher average as the core absorption height of the sample.

2.3.5. Moisture Permeability

Refer to the national standard moisture absorption test method for permeability. For each sample, cut three pieces with a diameter of 70mm. The testing surface should be the reverse side of the sample. The substance in the permeation cup should be anhydrous calcium chloride. The permeation test box should have a temperature of (38.0±2)°C and a relative humidity of (90.0±2)%. After equilibrating for 1 hour, immediately put the permeation cup into the silica gel dryer. After 30 minutes, carry out the first weighing. Repeat the entire process once, get the difference between the two weighings, and calculate the permeability through a formula. The test result for permeability is the average of the three samples.

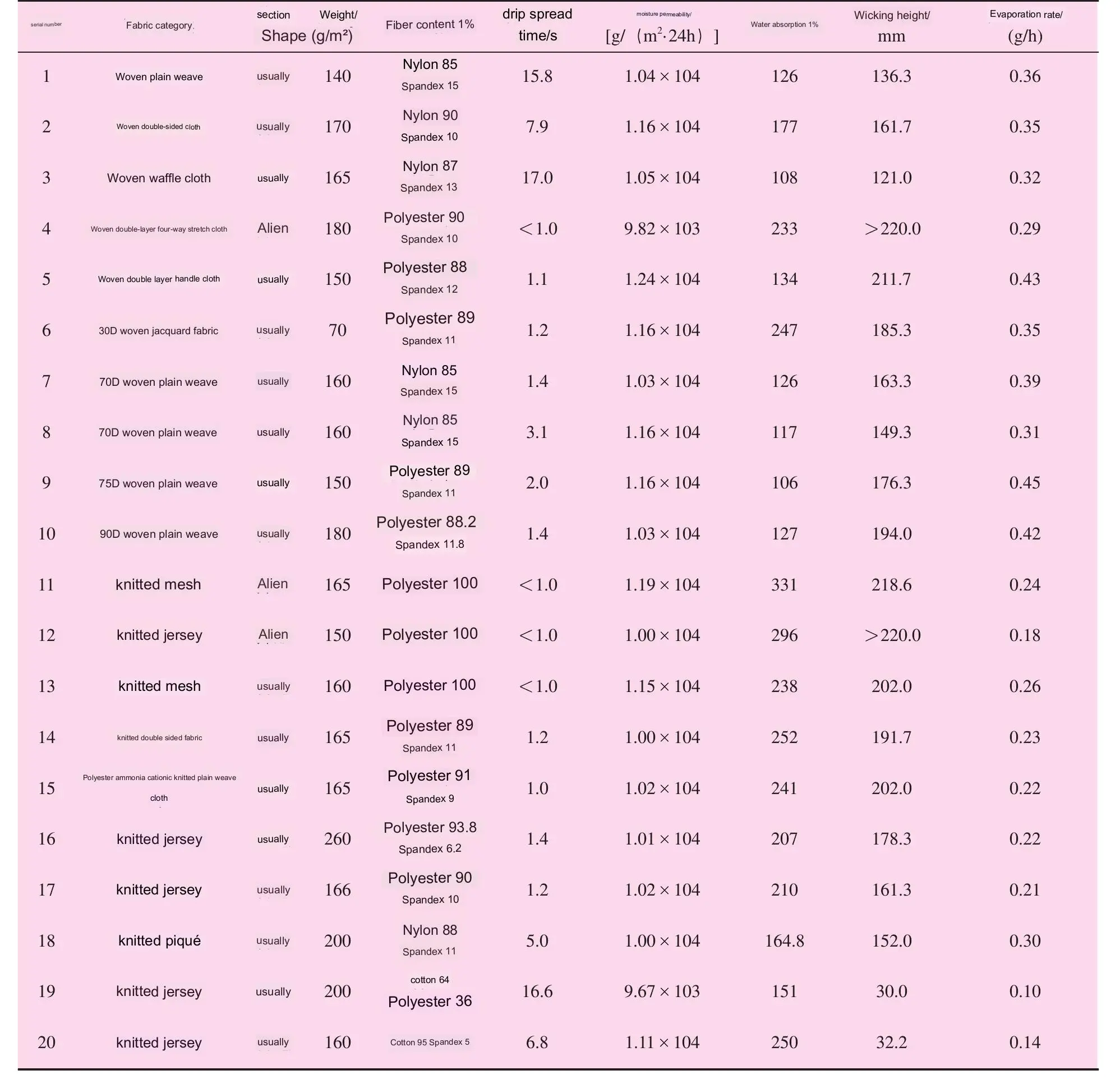

The test results for all samples can be seen in Table 1.

Table 1

3.Results Analysis

3.1 Moisture Absorption

The rapid moisture absorption of sports clothing is evident when the body sweats during exercise. The sports clothing fabric can quickly absorb sweat, helping the skin surface stay dry and comfortable . Referring to the standard GB/T 21665.1—2008, the moisture absorption of sports clothing fabric is characterized by the water absorption rate, water droplet diffusion time, and capillary height . The water absorption rate refers to the percentage of the water absorbed by the fabric to its original weight, with higher numbers indicating better moisture absorption . The test results from Table 1 show that knitted sportswear fabrics generally have higher water absorption rates than woven sportswear fabrics, due to their looser weave which favors water absorption. Even among woven fabrics, jacquard fabric has a higher absorption rate than denser fabrics, with low-twist yarn fabrics outperforming high-twist yarn fabrics. Cotton fabric’s absorption rate is higher than that of synthetic fibers, as cotton’s hydroxyl groups form hydrogen bonds with water molecules, leading to higher water absorption . The capillary action of irregular fibers influences the moisture absorption of the fabric; modified polyester fibers can improve fiber moisture absorption while increasing the fiber’s micro-pores, enlarging the specific surface area of the fiber, and enhancing its moisture absorption compared to ordinary polyester fibers. The time it takes for a droplet to diffuse and completely penetrate a sample indicates the fabric’s water absorption capability; shorter droplet diffusion times signify better absorption. Test results show that the droplet diffusion time of knitted sportswear fabrics is shorter than that of woven sportswear fabrics, due to the looser structure of knitted fabrics reducing the resistance to moisture transfer and thus shortening the diffusion time. The diffusion time of irregular polyester fibers is shorter than that of regular polyester fibers, due to the increased capillary action of irregular fibers aiding in water diffusion and the presence of grooves on the fiber surface, increasing the specific surface area and effectively shortening water diffusion time. The capillary height, a measure of capillary action, represents the height that moisture rises in the sample per unit time, serving as a key indicator of a fabric’s moisture conduction. The higher the capillary height, the better the moisture conduction. Table 1 shows that the moisture conduction of knitted sportswear fabric is generally better than woven sportswear fabric, which is also related to the organization structure of the two products; the looser the structure, the faster the moisture transfer, and the easier it is to wet the yarn. The capillary height of polyester blend fabrics is relatively high, demonstrating good moisture conduction, due to the small diameter of individual polyester fibers enhancing capillary action, with irregular fibers and surface grooves further enhancing this effect.

3.2 Quick-Drying

The quick-drying ability of sportswear fabric reflects its ability to disperse moisture, enabling the fabric to stay dry and enhance the comfort of sportswear. According to the standard GB/T 21665.1—2008, the quick-drying property of sports clothing fabric under liquid sweat conditions is characterized by the fabric’s evaporation rate and moisture permeability under standard atmospheric conditions . The evaporation rate is the mass of water evaporated per unit time, with larger numbers indicating better quick-drying. Test results show that the evaporation speed of woven fabric is generally faster than knitted fabric, as the higher absorption rate of knitted fabric slows down evaporation. The evaporation rate of synthetic fibers is higher than cotton fibers, due to cotton’s higher hydrophilic group count which forms hydrogen bonds with water molecules, making water less likely to evaporate and slowing the evaporation rate. Synthetic fibers, being more hydrophobic, evaporate water faster. Fibers with surface grooves or irregular fibers have a larger specific surface area, increasing the contact area between water and air inside the fabric, promoting water diffusion and drying . The moisture permeability refers to the mass of water vapor passing through a unit area of the sample in a certain time ; the higher the moisture permeability, the stronger the ability of water vapor to pass through the fabric. Fiber properties, fabric structure, coating or finishing can affect the moisture permeability of the fabric . The commonly collected moisture-absorbing and quick-drying sportswear fabrics have not been coated or finished, so the impact of these processes is relatively small. The test results from the table show that despite the different types and specifications of fabrics for moisture-absorbing and quick-drying products, their moisture permeability differs little, and all test results comply with the post-wash standard values of GB/T 21665.1—2008. In the GB/T 21665.1—2008 standard, moisture permeability characterizes the quick-drying property of the fabric, with higher permeability indicating better quick-drying. However, during the wearing process of sportswear, discomfort is often caused by a large amount of liquid sweat causing the clothing to stick to the skin. For clothing without waterproof requirements, its moisture permeability is generally enough to remove the latent sweat produced by the body, so whether moisture permeability should be a necessary assessment indicator for moisture-absorbing and quick-drying products requires further consideration and verification.

4.Conclusion

From the currently collected common moisture-absorbing and quick-drying sportswear fabrics, synthetic fibers are more widely used. Cotton fabric has good water absorption but slower evaporation rate, affecting its quick-drying ability. The fabric’s structure influences its moisture absorption and quick-drying properties; different fabric structures, even with the same fiber composition, have different moisture absorption and quick-drying abilities. Knitted fabrics generally outperform woven fabrics in terms of moisture absorption and quick-drying, mesh fabric or jacquard fabric outperforms plain fabric, and low-twist yarn fabrics outperform high-twist yarn fabrics. For irregular fiber fabrics, their increased specific surface area and presence of grooves on the fiber surface aid in improving moisture absorption and quick-drying; using modified polyester fibers can help improve the moisture absorption of the fabric.