Introduction

In today’s health and fitness trend, sportswear has become an essential part of our daily lives. But have you ever wondered how these comfortable and functional sportswear are made? This article delves into the production process, techniques, and the choice and characteristics of fabrics used in sportswear.

1. Key Steps in the Production Process

1.1 Fabric Selection

The choice of fabric for sportswear is the first step in its production process. Common fabrics include:

- Cotton: One of the most common fabrics, known for its moisture absorption, breathability, and softness. It’s ideal for summer sportswear but has drawbacks like poor abrasion resistance and shrinkage.

- Polyester: A synthetic fiber with qualities like durability, water resistance, and easy washing. It’s especially suitable for outdoor sportswear, but its breathability is inferior.

- Spandex: This fabric is highly elastic, making it particularly suitable for tight-fitting sportswear. However, its abrasion resistance is poor.

- Acrylic: A synthetic fiber known for its warmth, durability, and ease of washing, making it ideal for winter sportswear. However, its breathability is inferior.

- Wool: A natural fiber known for its warmth and breathability, ideal for winter sportswear. But it’s more expensive and prone to shrinkage.

- Bamboo Fiber: A new natural fiber with moisture absorption, antibacterial, and deodorant properties, suitable for various sportswear. But it’s more expensive.

The choice of fabric should be based on the style and functional requirements of the sportswear to ensure the final product is both comfortable and practical.

1.2 Cutting

Once the appropriate fabric is chosen, the next step is cutting. Based on the design blueprint, the selected fabric is cut into the required shapes and sizes. This step requires high precision to ensure each piece of fabric meets the design specifications.

1.3 Sewing

The cut fabric pieces are then sewn together to form the body of the sportswear. This step requires high skill and precision to ensure each garment meets the design specifications.

1.4 Finishing

This stage includes processes like washing, shaping, ironing, and decoration. These processes ensure the sportswear looks neat and has a good fit. For instance, washing removes any stains or chemical residues on the fabric, while ironing ensures the garment is smooth and wrinkle-free.

2. Sportswear Production Techniques and Their Characteristics

The production technique of sportswear is the core part of its production process. Different techniques affect the performance, appearance, and comfort of the garment. Below are some common production techniques and their characteristics:

- Flat Seam Technique: The most common sportswear production technique suitable for various fabrics and styles. Its main feature is the use of flat seams for sewing, with the stitching exposed. This technique is cost-effective and simple but may result in visible wear and tear on the stitching.

- Seam Sewing Technique: Suitable for various fabrics and styles. It uses a concealed stitch, with the stitching wrapped inside the fabric. This technique offers durable and aesthetically pleasing seams but is relatively more expensive.

- Adhesive Technique: Ideal for sportswear that requires elasticity and breathability. It uses an adhesive thread for sewing, with the stitching glued inside the fabric. This technique offers fewer stitches and comfort but is more expensive.

- Thermal Bonding Technique: Suitable for sportswear requiring breathability and elasticity. It uses a thermal bonding thread for sewing, with the stitching melting during the bonding process and merging with the fabric. This technique offers a seamless and comfortable finish but is more expensive.

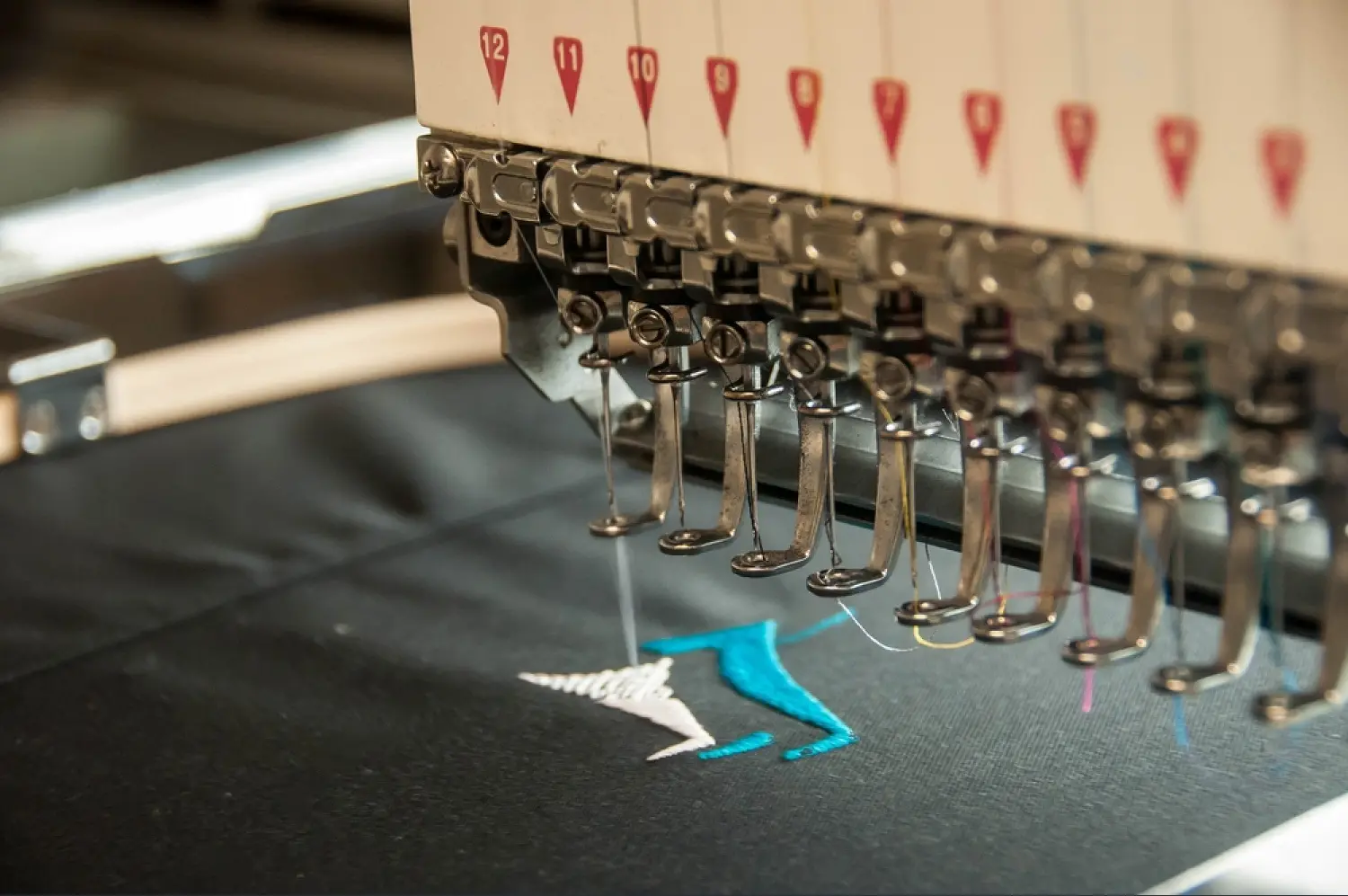

3. Types of LOGOs and Their Pros and Cons

In sportswear, the LOGO is not only a brand identifier but also serves decorative and promotional purposes. Here are some common types of LOGOs and their pros and cons:

- Embroidered LOGO: This method uses an embroidery machine to stitch the LOGO onto the garment.

- Pros: Durable and gives a high-quality feel.

- Cons: Relatively more expensive and may not be suitable for very intricate or small designs.

- Heat Transfer LOGO: This method transfers the LOGO from a special paper to the garment using high temperatures.

- Pros: Flexible and can print intricate designs in multiple colors. Fast production speed.

- Cons: Less durable, may fade or peel off after frequent washing. Not suitable for heat-sensitive fabrics.

- Screen Printing LOGO: This method uses a screen to print ink onto the garment.

- Pros: Durable and cost-effective for bulk production.

- Cons: Not suitable for very intricate designs. Limited to one color per print.

4. From Ordering to Receiving: The Role of the Factory

When a customer places an order for sportswear, the role of the factory is not just production. Here are the main tasks the factory needs to complete from the time of order to the customer receiving the goods:

- Order Confirmation: Once the order is received, the factory needs to confirm the details of the order, such as style, quantity, fabric selection, etc.

- Production Planning: Based on the order requirements, the factory will develop a production plan to ensure timely completion.

- Production: This includes the aforementioned fabric selection, cutting, sewing, and finishing steps.

- Quality Check: After production, the factory conducts a quality check to ensure each piece of sportswear meets the standards.

- Packaging and Shipping: Sportswear that passes the quality check is packaged and shipped to the customer.

- Customer Service: After the customer receives the goods, the factory provides services like returns, exchanges, and post-purchase inquiries.

5. Conclusion

The production of sportswear is not just a simple manufacturing process; it involves multiple stages and details. From fabric selection to final delivery, each step requires meticulous planning and execution by the factory. Through this article, we hope you have gained a comprehensive understanding of the production process and techniques of sportswear.